The Railway Pad is a resilient component designed to provide vibration isolation, noise reduction, and protection to railway tracks and infrastructure, ensuring smooth and efficient train operations while minimizing wear and damage.

Vibration Isolation: Railway Pads are specifically engineered to absorb and isolate vibrations generated by passing trains, reducing the transmission of vibrations to the surrounding infrastructure and minimizing the potential for structural damage.

Noise Reduction: They are designed to dampen and attenuate the noise generated by train wheels on the tracks, helping to mitigate noise pollution and create a more comfortable environment for nearby residents and passengers.

Resilience and Durability: Railway Pads are manufactured from resilient materials, such as rubber or synthetic elastomers, that exhibit excellent durability, resistance to weathering, and long-term performance under heavy loads and harsh environmental conditions.

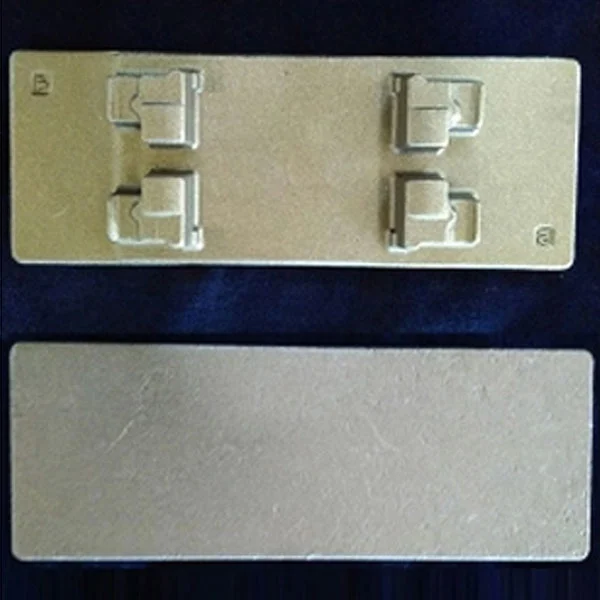

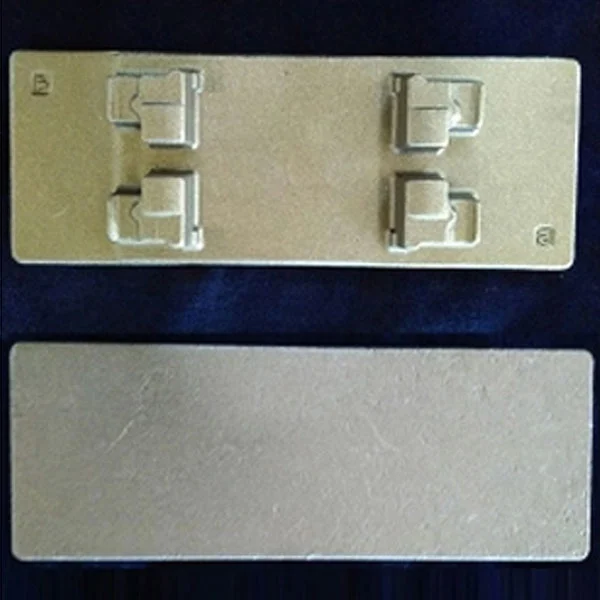

Track Infrastructure: Railway Pads are installed between the rail and the railroad ties or sleepers to provide cushioning, vibration isolation, and protection to the track infrastructure. They help to reduce the wear and tear on the track components, prolonging their lifespan and minimizing maintenance requirements.

Noise Mitigation: Railway Pads are used to reduce the noise generated by train operations. They help dampen the vibrations and impact noise produced by the train wheels on the tracks, contributing to noise reduction in residential areas or sensitive environments located near railway lines.

Place of Origin | China |

Application Industries | Rail transit |

packing | customized |

size | Customized(According to customer drawings) |

logo | customized |

port | Shanghai |

samples | Customized |

Technical | Stamping |

Metal Material | alloy steel |

lead time | 30-45days |

Mold | customized |

MOQ | 1 piece |

service | OEM/ODM |