We have the first 20T fully hydraulic forging hammer production line in China, which is capable of producing large precision drop-forged parts with a bearing surface of 406,944 square millimetres and approximately 500 kg, with beautiful shapes.

We have the first 20T fully hydraulic forging hammer production line in China, which is capable of producing large precision drop-forged parts with a bearing surface of 406,944 square millimetres and approximately 500 kg, with beautiful shapes.

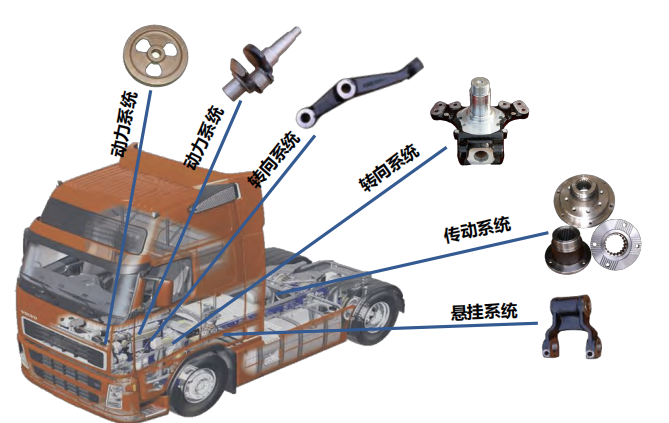

JimaFor has 3 forging production lines, China's first 20T full hydraulic forging hammer production line, which can produce large precision die forgings with a bearing surface of 406944mm², about 500kg, with beautiful forming. The production line produced 104 substrates, fishtail plate, 526, 393 front axle northbound products won the Forging Association quality forging award. Equipped with 3 tons full hydraulic free forging hammer production line, can produce all kinds of 5CrMnMo, 5CrNiMo, H13 die steel modules and other ordinary carbon steel and alloy steel free forgings. Equipped with a 3 ton hydraulic hammer production line, all kinds of small and medium-sized custom metal forgings can be produced. At the same time, it is equipped with a walking gas heat treatment line, six bench heating furnaces and a 40T oil quenching line, which can realize the heat treatment of large and medium-sized dies and other large and medium-sized die forgings.

JimaFor, an outstanding metal parts China brand, has three presses of 4000T, and 5000T,800T. two warm forging lines; one vacuum quenching furnace; two fully automatic warm forging production lines.

Our custom metal casting includes sand casting, metal mold casting and die casting technology. Sand casting is suitable for small and medium-sized parts, metal mold casting is suitable for large and high-precision parts, and die casting technology is suitable for high-volume, high-precision and complex-shaped parts. Our equipment is equipped with advanced control systems and quality monitoring equipment to ensure stable production processes and excellent component quality. Regardless of size or complexity, our casting equipment meets the requirements for high quality and efficiency.

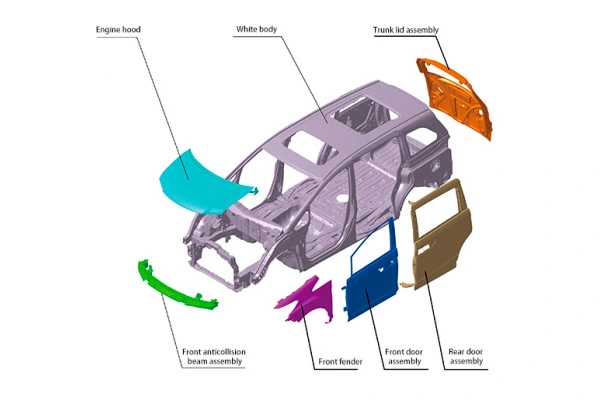

We have advanced stamping equipment for cutting and forming metal parts. Our stamping equipment uses high-precision molds and automated control systems to achieve fast and precise processing. Whether it is thin or thick plates, our metal stamping equipment can meet the requirements of different materials and thicknesses. Through precise control of punching force and speed, we are able to produce parts that meet design requirements and ensure consistency in size and shape. Our stamping equipment also has efficient automatic feeding and discharging systems, which improves production efficiency.

Classification | Capacity | Typical part |

Small | 3,150 - 12,500 kN | Reinforcement, beam, support, hinge, recessed grip |

Medium | 16,000 - 25,000 kN | Door sill, hinge reinforcement, B-pillar, side member, roof frame, recesses for tank |

Large | 30,000 - 45,000 kN | Fender, hood, deck lid, door inner, outer door skin |

Super large | 50,000 - 90,000 kN | Roof, roof frame, side aperture, floor pan, outer door skin (double) |

We have advanced heat treatment equipment, including high temperature furnaces, quenching equipment and tempering furnaces. These devices can heat, rapidly cool and heat-treat metal spare parts to improve their hardness, strength and wear resistance. Our heat treatment equipment is equipped with precise temperature control systems to ensure the accuracy and stability of the treatment process. Whether in the aerospace, automotive or construction machinery fields, our heat treatment equipment can meet the needs of various industries for high-quality parts.

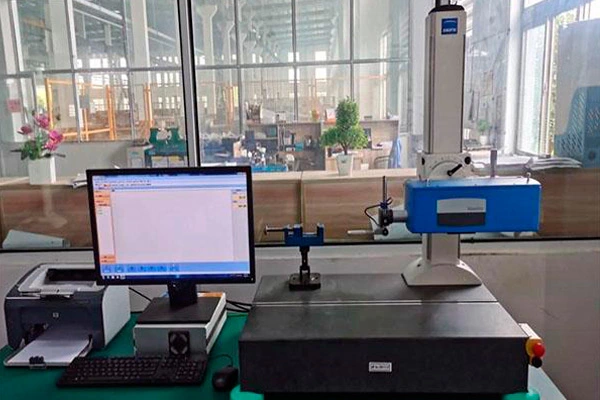

We have more than 40 sets of complete and advanced testing equipment: spectrum analyzers, metallographic microscopes, tensile testing machines.

Low temperature impact testing machine, X-ray flaw detection machine, magnetic particle flaw detection machine, ultrasonic flaw detection machine, three-dimensional coordinate measuring instrument, image measuring instrument, 3D scanner. The above-mentioned equipment can ensure that precision castings with high standards are provided to customers and meet their comprehensive testing requirements for physical and chemical properties of materials, non-destructive defect testing, and high-precision geometric dimension testing.

The machining workshop is equipped with a front shaft finishing production line, more than 10 sets of various precision machines, 8 sets of precision CNC machining centers and 10 sets of CNC lathes. It can realize precision processing of all kinds of rail transit forgings and heavy truck forgings.

Fully automatic machining production line (4 lines ); Robot machning production line (2 lines)